Modern post-bed high-speed machine - Electronic version

Single and double-needle post bed machines with the PFAFF INDUSTRIAL brand are the most-used equipment in the shoe industry. PFAFF has succeeded in achieving a true upgrade of this legendary machine generation with the new series 1571/ 1574 / 1591. The modern and new designed case in the new PFAFF product lead design, the sturdy thread trimmer as well as the automatic hook lubrication are the distinguishing features of this new product range. The machines are equipped with integrated, energy saving drives. This range is mostly used for nearly all top-stitching work with single or two needles in the shoe production. Ornamental and assembly seams on classic and sport shoes can be sewn easily and in a top seam quality. The whole range of light to medium-heavy materials is covered here. The machines guarantee maximum performance and quality at an extremely attractive price – reason enough for many well-known manufacturers to use PFAFF post bed machines for their production.Features

- New high-class design of this classic PFAFF machine for the shoe industry

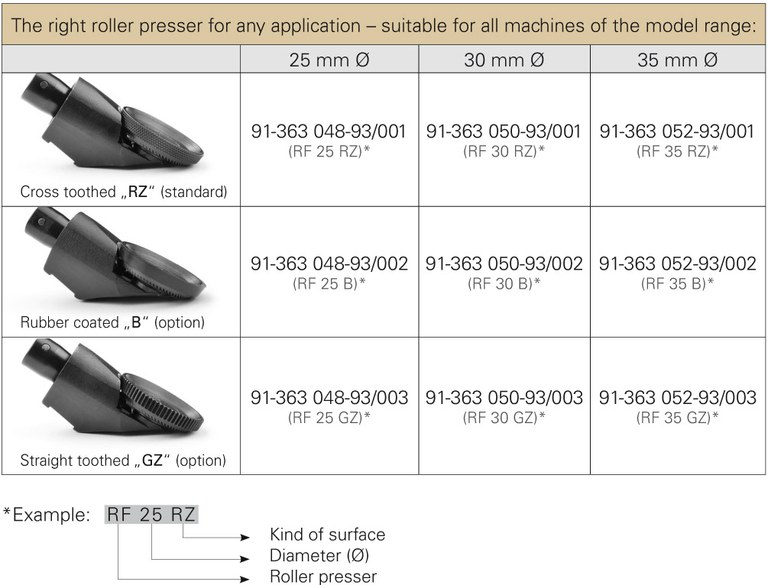

- Three roller presser versions available: cross toothed, rubber coated, straight toothed

- Guaranteed „Stitch in stitch“ backtacking – no perforation of material

- Exact accurate stitch length can be reproduced at any time

- Stitch length setting are identical from machine to machine

- Seam length programming by control panel

- Active differential feed can be called anytime during sewing

- Top-quality for all assembly and decorative seams

- Simple adjustment of stitch length and number of backstack stitches via control panel

- Easily adjustable thread trimmer for short thread ends (up to 15/3 syn.)

- Electromagnetic controlled functions for thread trimming and presser foot lifting

- Overload clutch for hook protection

- Edge guide for an accurate and consistent seam distance to the edge

- A multi-function switch with pre-programmed functions is integrated in the sewing head - Reverse sewing / intermediate tacking, Backtack inversion, Needle up, without trimming

- ½ stitch length for corner stitch, target stitch or programmable stitch

- -725/04: Edge trimming mechanism, bottom driven (option)

- The LED light, which is built into the sewing head, creates optimum illumination of the sewing area

- No compressed air required

- Hand wheel within easy reach of the operator

Applications

Twin needle assembly and topstitching seams in shoes, leather goods and automotive interior

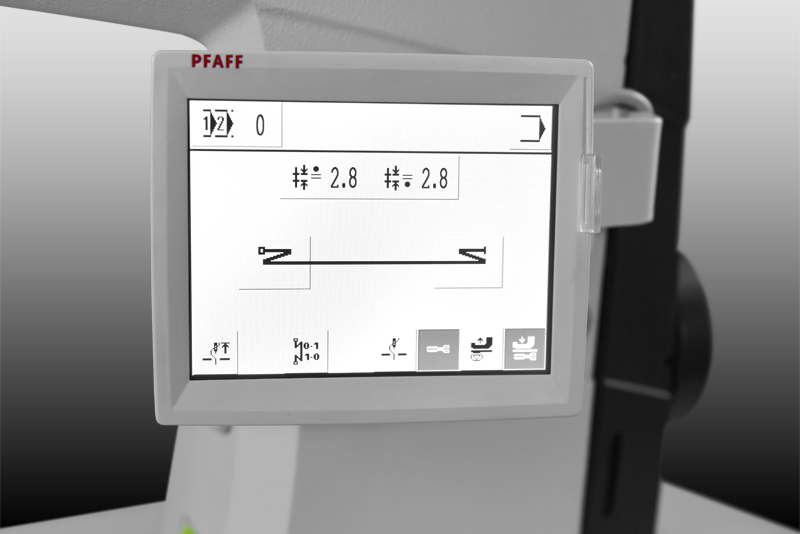

Optional PFAFF P1 touch panel

- Easy data exchange between machines via SD-card reader, USB-slot or multi-card-reader

- Quick and easy generation of sewing programs via the touch panel

- Seam programming based on the teach-in method

- Graphic display of all areas with extra fullness

- Easy selection from

- manual sewing

- sewing with program routine (knee switch)

- programmed sewing (99 sewing programs each featuring up to 99 sewing areas)

Specifications

Needle system: 134-35 S Needle size: Version B 90 Nm, Version C 130 Nm Max. sewing speeds: 3.000 s.p.m Max. stitch length: 7,0 mm Diameter of roller presser: 30mm (Option depending on the version: 25 mm or 35 mm) Stitch type: 301 (Lockstitch) Clearance under roller presser: max. 10,0 mm Clear workspace: 245 x 275 mm Connection voltage: single-phase a.c. 230 V, 50/60 HzLeaflet TL_571_574_591_10-14 570_590_1570_1590e (1) Parts Book TL_1571_1574_1591_10-14_DE_EN_ES_ZH